Rubber Parts Sourcing

Product outsourcing services have become increasingly popular in recent years, as businesses seek to streamline their operations and reduce costs. One country that has emerged as a key player in the outsourcing industry is Vietnam. With its competitive labor costs, favorable business environment, and skilled workforce, Vietnam offers a range of outsourcing services, including rubber parts sourcing through transfer molding.

Transfer molding is a commonly used method for manufacturing plastic packages in integrated circuit technology. It involves the use of a thermosetting material that is transferred under pressure into a closed mold. Thermosets are polymers that are fluid at low temperatures and react irreversibly when heated to form a cross-linked network that cannot be melted.

Transfer molding is a commonly used method for manufacturing plastic packages in integrated circuit technology. It involves the use of a thermosetting material that is transferred under pressure into a closed mold. Thermosets are polymers that are fluid at low temperatures and react irreversibly when heated to form a cross-linked network that cannot be melted.

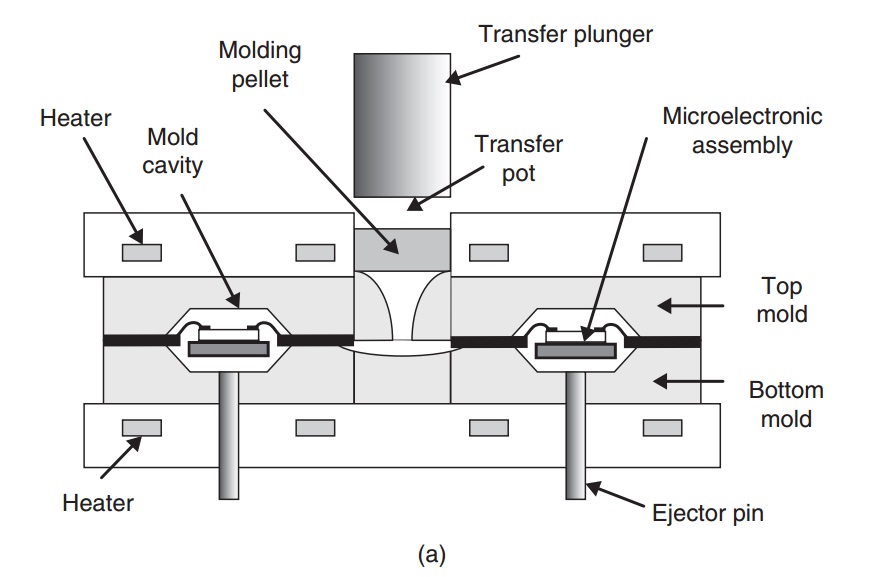

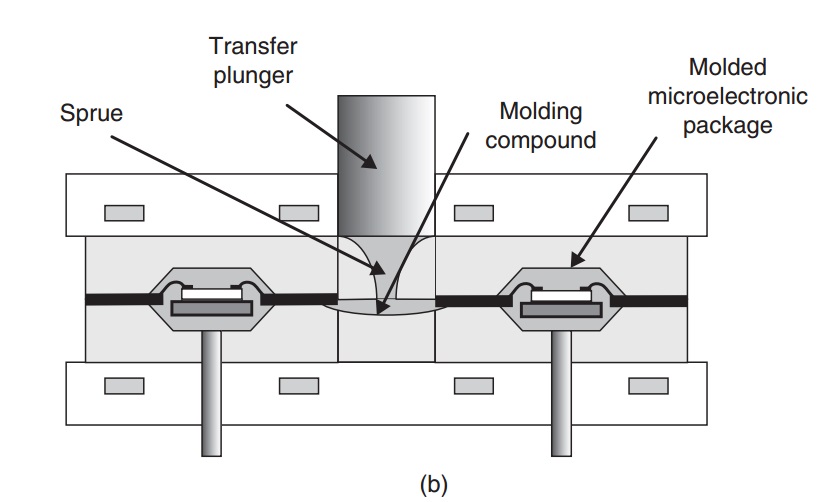

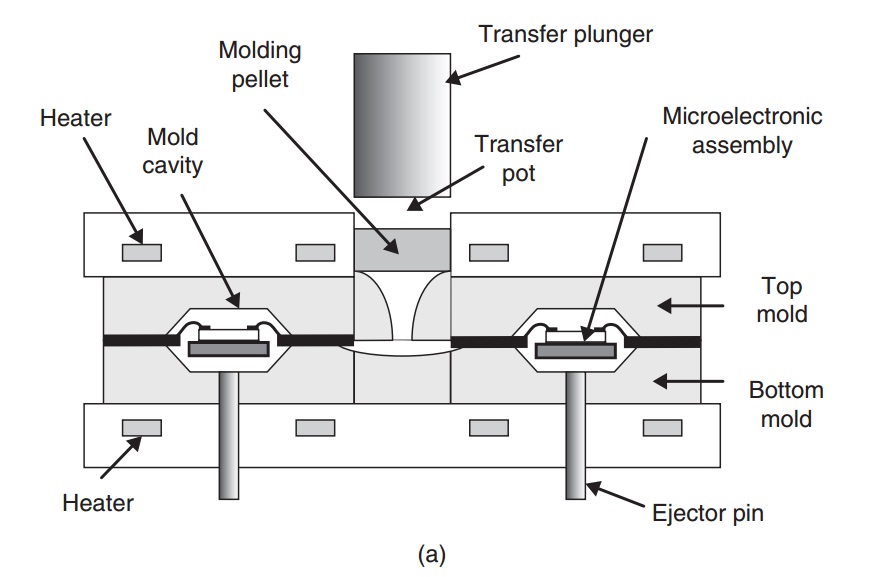

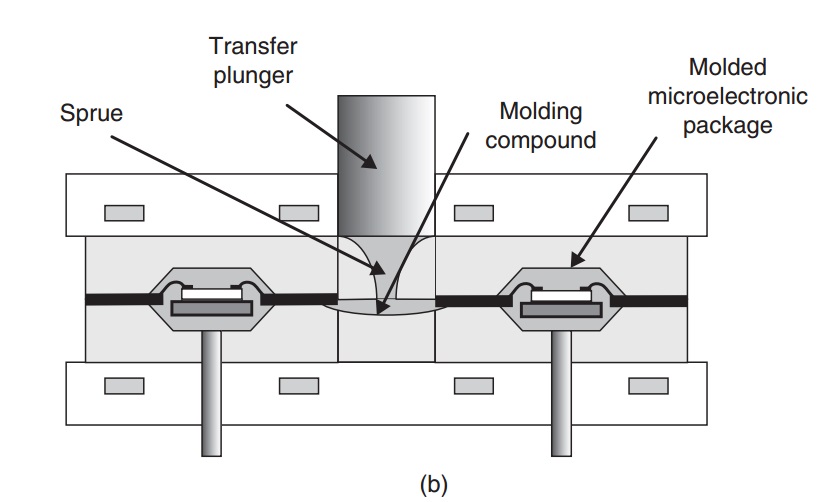

The transfer molding process typically begins with the preheating of the molding compound, also known as the preform or pellet. The preform is placed in an auxiliary chamber called the transfer pot. A transfer plunger then forces the preform to flow through runners and gates into the closed cavity or cavities of the mold. The high pressure involved in the injection molding process makes transfer molding particularly suitable for parts with inserts.

The transfer molding process typically begins with the preheating of the molding compound, also known as the preform or pellet. The preform is placed in an auxiliary chamber called the transfer pot. A transfer plunger then forces the preform to flow through runners and gates into the closed cavity or cavities of the mold. The high pressure involved in the injection molding process makes transfer molding particularly suitable for parts with inserts.

There are several advantages to using transfer molding for rubber parts sourcing. Firstly, the process allows for greater control over the flow and distribution of the thermosetting material, resulting in more precise and consistent parts. This is particularly important for applications where tight tolerances and quality standards are required.

Secondly, transfer molding is a cost-effective solution for producing rubber parts with inserts. Inserts can be pre-placed in the mold before the material is injected, providing enhanced structural integrity and reducing the need for additional assembly steps. This not only saves time and labor costs but also ensures that the inserts are securely bonded to the molded part.

Furthermore, transfer molding offers excellent dimensional stability and surface finish, making it suitable for high-quality rubber parts. The closed mold design helps to prevent variations in part dimensions, resulting in consistent and reliable products. Additionally, the pressure applied during the transfer molding process helps to eliminate surface defects, enhancing the aesthetic appeal of the finished parts.

In Vietnam, the transfer molding process is widely utilized for rubber parts sourcing. The country's manufacturing sector has seen significant growth in recent years, attracting both domestic and foreign investment. Vietnam offers competitive labor costs, which remains one of its main advantages in the outsourcing market.

Moreover, the business environment in Vietnam is supportive of foreign investment, with various incentives and policies in place to attract companies looking to outsource their manufacturing processes. The government has implemented measures to simplify regulatory procedures, reduce bureaucracy, and improve infrastructure, making the country an attractive destination for businesses seeking to outsource their rubber parts production.

Vietnam also boasts a skilled and dedicated workforce, with a strong focus on technical education and training. The country has numerous universities and vocational schools that provide specialized training in engineering and manufacturing. This ensures that there is a pool of skilled workers available for the transfer molding process.

Furthermore, Vietnam's proximity to major markets, such as China and Southeast Asia, offers logistical advantages for businesses outsourcing their rubber parts sourcing. The country has well-developed transportation networks, including seaports, airports, and highways, facilitating the efficient movement of goods.

In conclusion, product outsourcing services in Vietnam, specifically rubber parts sourcing through transfer molding, offer numerous advantages for businesses looking to streamline operations and reduce costs. The transfer molding process provides precise and consistent parts, while also allowing for the integration of inserts. Vietnam's competitive labor costs, supportive business environment, skilled workforce, and favorable logistical location make it an ideal destination for companies seeking to outsource their rubber parts production. With these advantages, Vietnam is poised to further establish itself as a key player in the global outsourcing industry.

Transfer molding is a commonly used method for manufacturing plastic packages in integrated circuit technology. It involves the use of a thermosetting material that is transferred under pressure into a closed mold. Thermosets are polymers that are fluid at low temperatures and react irreversibly when heated to form a cross-linked network that cannot be melted.

Transfer molding is a commonly used method for manufacturing plastic packages in integrated circuit technology. It involves the use of a thermosetting material that is transferred under pressure into a closed mold. Thermosets are polymers that are fluid at low temperatures and react irreversibly when heated to form a cross-linked network that cannot be melted. The transfer molding process typically begins with the preheating of the molding compound, also known as the preform or pellet. The preform is placed in an auxiliary chamber called the transfer pot. A transfer plunger then forces the preform to flow through runners and gates into the closed cavity or cavities of the mold. The high pressure involved in the injection molding process makes transfer molding particularly suitable for parts with inserts.

The transfer molding process typically begins with the preheating of the molding compound, also known as the preform or pellet. The preform is placed in an auxiliary chamber called the transfer pot. A transfer plunger then forces the preform to flow through runners and gates into the closed cavity or cavities of the mold. The high pressure involved in the injection molding process makes transfer molding particularly suitable for parts with inserts.There are several advantages to using transfer molding for rubber parts sourcing. Firstly, the process allows for greater control over the flow and distribution of the thermosetting material, resulting in more precise and consistent parts. This is particularly important for applications where tight tolerances and quality standards are required.

Secondly, transfer molding is a cost-effective solution for producing rubber parts with inserts. Inserts can be pre-placed in the mold before the material is injected, providing enhanced structural integrity and reducing the need for additional assembly steps. This not only saves time and labor costs but also ensures that the inserts are securely bonded to the molded part.

Furthermore, transfer molding offers excellent dimensional stability and surface finish, making it suitable for high-quality rubber parts. The closed mold design helps to prevent variations in part dimensions, resulting in consistent and reliable products. Additionally, the pressure applied during the transfer molding process helps to eliminate surface defects, enhancing the aesthetic appeal of the finished parts.

In Vietnam, the transfer molding process is widely utilized for rubber parts sourcing. The country's manufacturing sector has seen significant growth in recent years, attracting both domestic and foreign investment. Vietnam offers competitive labor costs, which remains one of its main advantages in the outsourcing market.

Moreover, the business environment in Vietnam is supportive of foreign investment, with various incentives and policies in place to attract companies looking to outsource their manufacturing processes. The government has implemented measures to simplify regulatory procedures, reduce bureaucracy, and improve infrastructure, making the country an attractive destination for businesses seeking to outsource their rubber parts production.

Vietnam also boasts a skilled and dedicated workforce, with a strong focus on technical education and training. The country has numerous universities and vocational schools that provide specialized training in engineering and manufacturing. This ensures that there is a pool of skilled workers available for the transfer molding process.

Furthermore, Vietnam's proximity to major markets, such as China and Southeast Asia, offers logistical advantages for businesses outsourcing their rubber parts sourcing. The country has well-developed transportation networks, including seaports, airports, and highways, facilitating the efficient movement of goods.

In conclusion, product outsourcing services in Vietnam, specifically rubber parts sourcing through transfer molding, offer numerous advantages for businesses looking to streamline operations and reduce costs. The transfer molding process provides precise and consistent parts, while also allowing for the integration of inserts. Vietnam's competitive labor costs, supportive business environment, skilled workforce, and favorable logistical location make it an ideal destination for companies seeking to outsource their rubber parts production. With these advantages, Vietnam is poised to further establish itself as a key player in the global outsourcing industry.

CATEGORIES

CONTACT US

Whatsapp: +1 (213)2423492

Phone: +1 (213)2423492

Tel: +1 (213)2423492

Email: info#vinful.com (Replace # to @)

Addr: 90 STATE STREET, SUITE 700, OFFICE 40, ALBANY, NY, United States, 12207